I've been attending the Nats , for the past few years, and always wanted to stunt but, I cannot see spending all week flying one event, stunt, where I could be flying about ten. Now enters 1/2A Stunt, the event that's held on Saturday after the Walker Cup flyoff and after all other venues are completed.

I generaly take a different approach to building my subjects, I like stuff that's too cool. This would also give me a change to run one of my engines, on full pipe, in a stunt ship. Now there are lots of good designs out there but, I have chosen the Tempest II, a proven winner and, one where the plans were done in ACAD and can easily be edited since, I was going to reduce the size to 53% of the original. I then contacted Randy Smith of Aero Products for the plans, he was kind enough to e-mail them to me with one provision, I am not to give or sell them, so don't ask me. I will be providing Randy with updates and changes to the design and I'm sure he will make them available to any requesters once this project is completed.

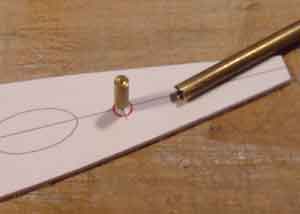

I generaly start a project with the wing. I've copied the ribs and layed them out so they would fit on a 3" wide sheet of balsa and then, attached them to the balsa with "3M Scotch, Restickable Adhesive", which is available at any stationary store. These will allow you to cut the ribs out and sand, across the rib to clean up any cutting imperfictions. I will be building on a wing jig, the photo to the right shows a pin I've made that fits in a 5/32" OD brass tube so as to drill the holes for the wing jig rods.

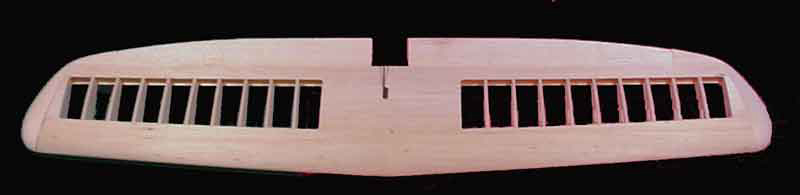

To the right is the wing positioned on the wing jig, note the rubber bands and paper clips to hold the LE and TE onto the ribs before glueing. The spacing for the 1/16" ribs where a bit tight so, I only used every other holder to support the rods. When using this fixture, your limited to attaching only the LE, TE, and top spar but, at least it gets you started in making it straight. After removal, you can install the bellcrank, bottom spar and sheeting, which is 1/32". Picture below is the bellcrank, typical 'big' style at a weight of 2 gm, I'll be using .025" solid leadouts and 1/6" wire to the flap horn.

Wood weights are 4- 4.5 lb for ribs, sheeting,flaps, and tips, use 7-8 lb for spars, LE and, TE.

Here's a tip even, for you pro's, use some Scotch Magic Tape on the end of the wing to protect the top sheeting when sanding the tips to shape, as photo to the right shows. The inboard tip has adjustable leadouts using the slot and eyelet style and the outboard, has a weight box added.

Below is the finished wing less horn, 1.97 oz.

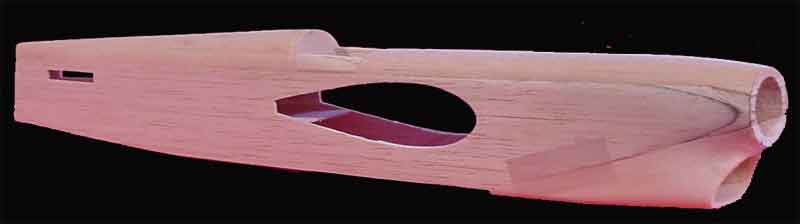

Nose construction is straight forward just like the big ones except, I've used shorter motor mounts, I don't think there's going to as much stress and vibration with the smaller, high reving 1/2A engine.

Fus sides are 1/6" balsa and 1/16" balsa doublers with .3 oz carbon mat sandwiched between, 1/4" square red oak motor mounts and 3/32" ply bulkheads.

Below, it's starting to look like something, weight pictured is 1.2 oz.

Now comes the fun part, the canopy. I'll have to form one up and here's where I start, on the right, I make an outline of the shape and tape under the area. Apply Bondo to fill in the voids as shown below.

Fill in any bubbles with more Bondo and below is the roughed out shape, this will be sanded with 320 grit as the finish.

Work one side at a time, use a knife to carve while it's still alittle rubbery then sand with 100 grit to shape.

Click here for