NEW REED EXPERIMENT

I've often thought about improving the current reed system used on the Cox engine, there's got to be a better way.

By looking at current reed induction systems used by motorcycles, snowmobiles and the like, they use a system that secures the reed at one end and not two ends like the Cox, this requires less force to open and doesn't restrict the amount of the opening, to a degree. Plus, I feel the current design is less efficient than the straight through and angled design that I've come up with, I mean the incoming charge has to curve around the reed with the stock system.

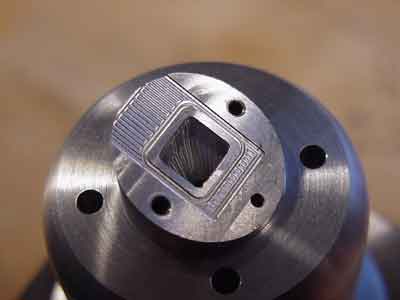

The system pictured is using a standard Cox mylar reed, it is flexable enough to try different materials and thickness to, I hope, obtain an increase in RPM vs. the stock, Cox system.

The reed is pined at one end and it's holder is secured by 0-80 cap srcews. The one hazard is the screws loosing but, I having thought of any other means yet.

The holder has a gentle curve machined into it to keep, I hope, the reed from permately retaining any distortion and to remain flat.